123 Prodotti

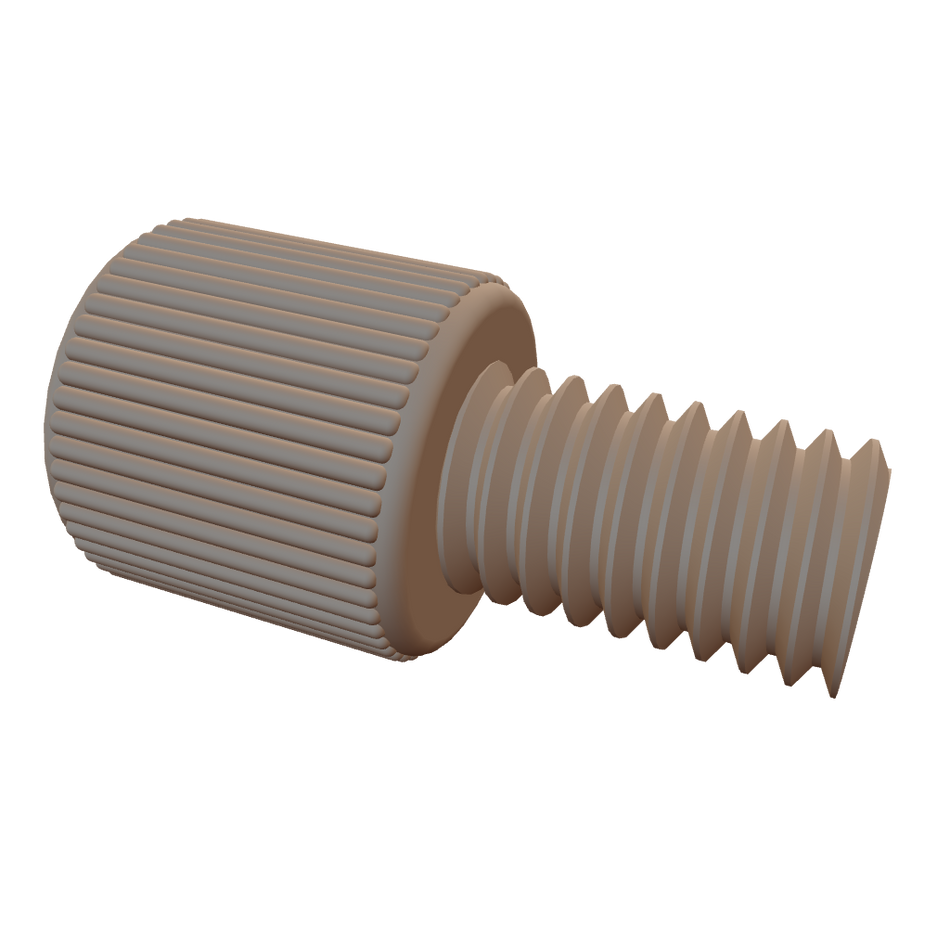

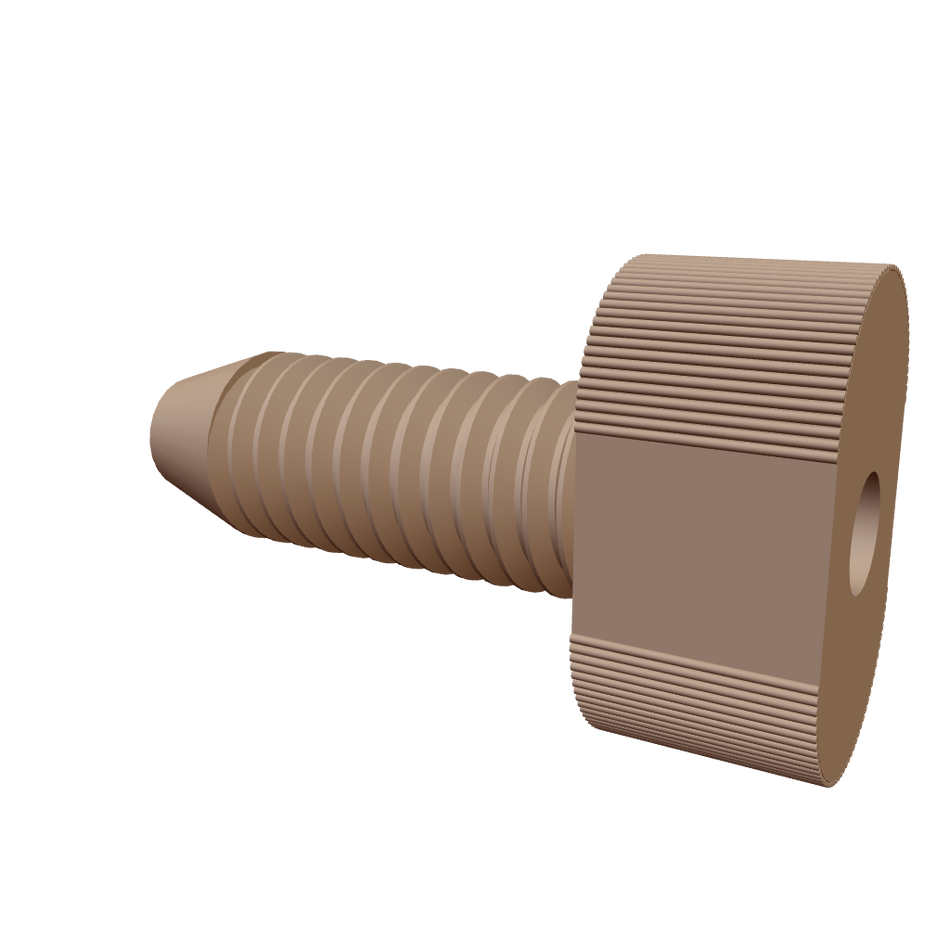

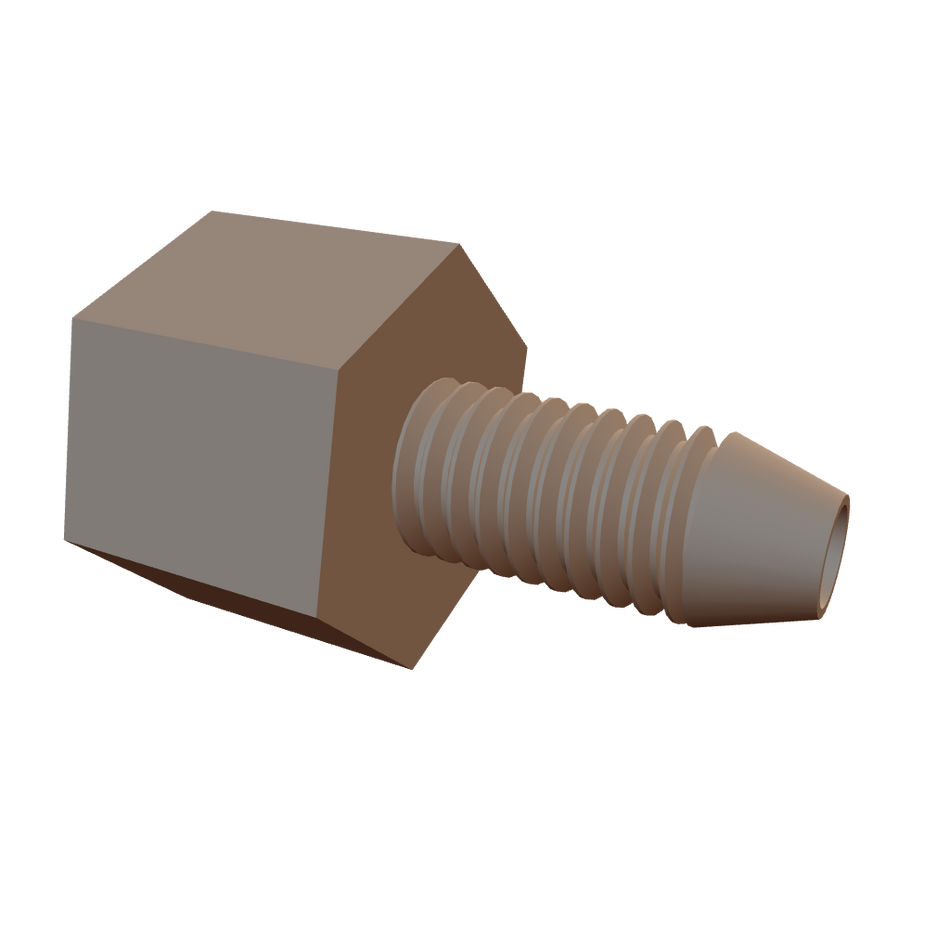

La tecnologia sottomarina e il suo utilizzo di viti, dadi, bulloni e dispositivi di fissaggio in polimeri

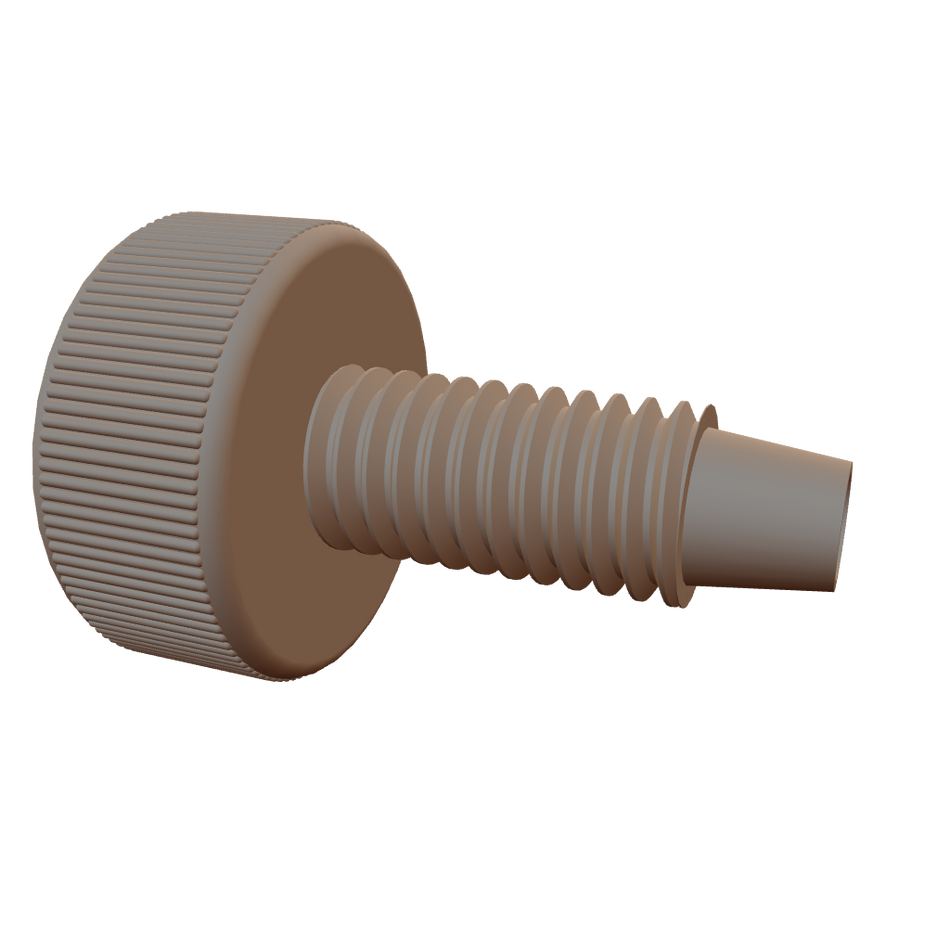

Il settore sottomarino, che comprende industrie come il petrolio e il gas offshore, l'energia rinnovabile (come i parchi eolici) e l'esplorazione in acque profonde, opera in ambienti subacquei estremi che richiedono materiali robusti e resistenti alla corrosione. I dispositivi di fissaggio in polimeri sono diventati sempre più importanti in questo settore grazie alle loro proprietà di leggerezza, elevata resistenza alla corrosione e capacità di sopportare pressioni elevate e condizioni difficili. A differenza dei tradizionali elementi di fissaggio in metallo, i polimeri, in particolare i tecnopolimeri avanzati come il PEEK (Polietereterchetone), non sono conduttivi e riducono il rischio di corrosione galvanica quando vengono utilizzati insieme ad altri materiali. Il loro utilizzo contribuisce a migliorare la longevità e le prestazioni delle infrastrutture sottomarine, riducendo al contempo i costi di manutenzione.